Projected Capacitive vs. Infrared Touch Screens

Following the successful launch of our new Projected Capacitive (PCAP) Touch Screens with Dual OS one of the most pressing questions we have heard is what the difference is between the technology used in our new PCAP touch screens and the Infrared (IR) touch technology that we have used since we launched our touch screens. How are they different though and more importantly which is better?

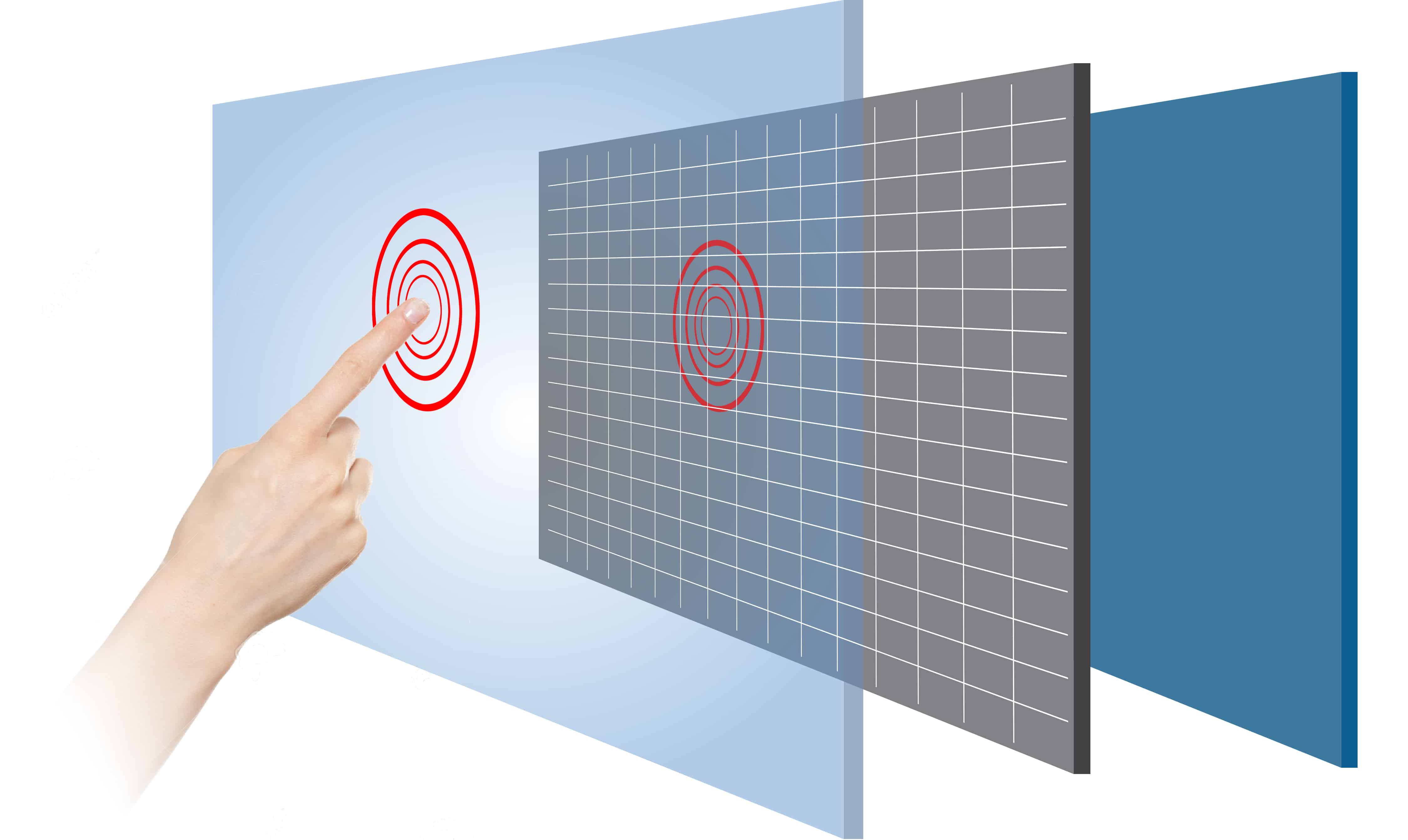

Projected Capacitive technology (more commonly referred to as PCAP) is the new kid on the block when it comes to touch technology. It is the same technology though that is used in smartphones and tablets due to its high levels of accuracy and speedy response times. The way PCAP touch technology works is by fixing a sensor grid between a layer of cover glass and the LCD panel, so when a finger touches the glass the grid detects the coordinates of the touch point. This is shown in the diagram below.

With this type of technology no recessed bezel is required so our PCAP Touch Screens with Dual OS have a strong tempered edge-to-edge glass front for a more striking display. From easy cleaning to smooth gesture recognition PCAP is the definitive touch technology. This however comes at a cost as PCAP touch screens can be up to 60% more expensive than their Infrared counterparts. It also has limitations on how large it can scale, at this moment the largest market ready solution that we have is a 42” PCAP touch screen. Allsee uses Projected Capacitive touch technology in our PCAP Touch Screens with Dual OS.

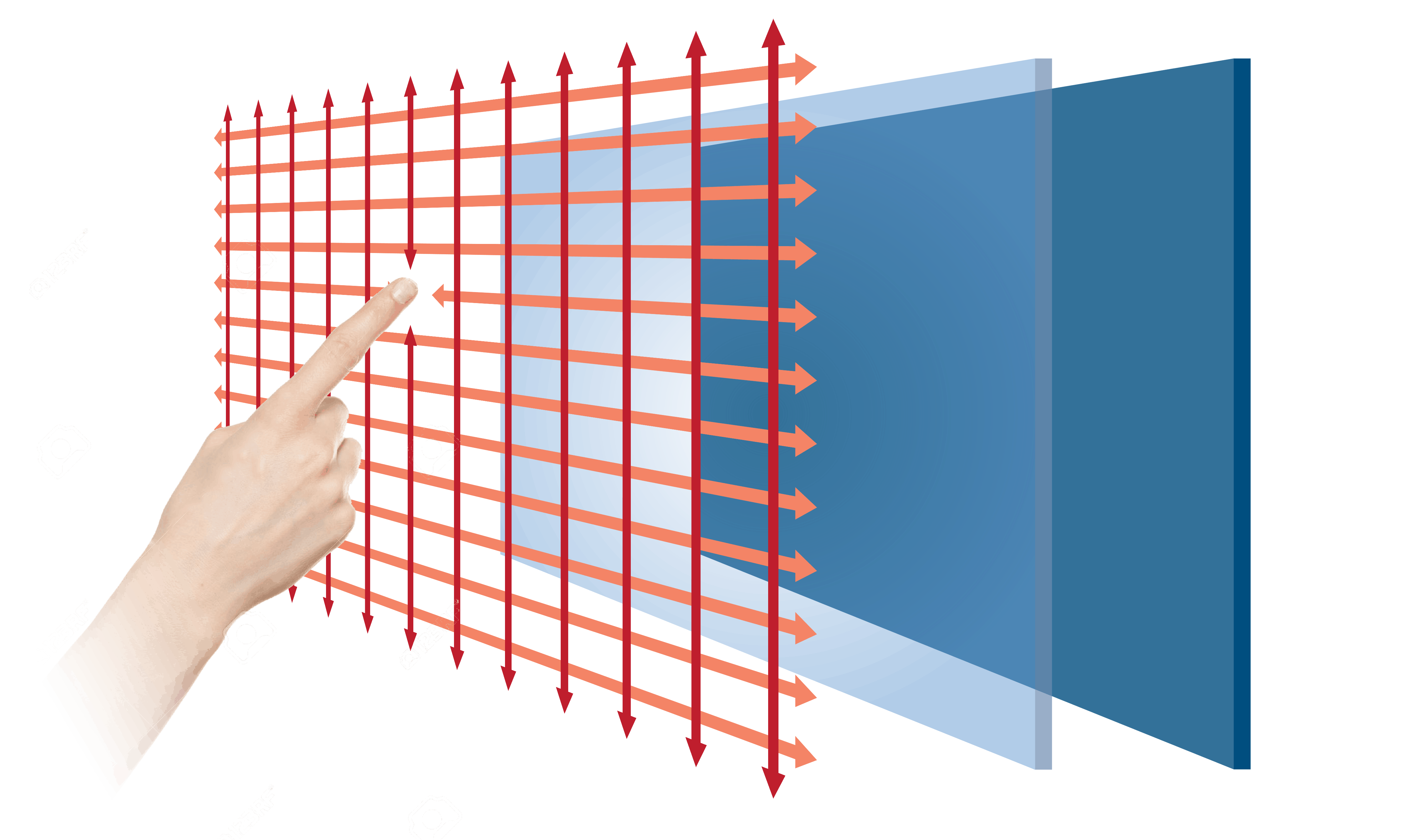

Infrared touch technology (also known as IR) is the most widely used touch screen in commercial applications and has been the industry standard for decades. Using IR technology means that no actual contact with the screen is required so less damge is incurred over time. It works by embedding LED lights and sensors into the bezel of a monitor above the glass. These LED’s beam a signal across to the corresponding sensor on the other side forming an invisible grid. When the grid is broken by a finger, or other solid object, the sensors can detect the touch point. This is shown in the diagram below.

A bezel will always be required when IR is used due to the way it works. There is no chance of edge-to-edge glass being used with IR. However unlike PCAP, IR technology can scale to very large sizes with no drop in quality. The largest IR touch screen we have produced has been a staggering 84”. Allsee uses Infrared touch technology in a variety of different products. From our Infrared Wall Mounted range, the Infrared Freestanding and Infrared Kiosks to our Interactive touch Displays which also use IR touch technology.

PCAP and Infrared are the two most suitable forms of technology used in commercial touch screens.

Both are great but depending on the customer’s requirements one may be more suitable than the other.PCAP is the touch technology of the future but it does come at a larger upfront cost. Infrared is the tried and trusted staple of touch technology. If you are looking for a more budget friendly touch screen then I suggest choosing an Infrared touch screen. If you are willing to invest then a PCAP touch screen will be worth every penny. There is no right or wrong answer when it comes to picking between the two; it is simply a matter of suitability.

Tom Rock is a Marketing Manager for Allsee Technologies. His background is in Digital Signage and Graphic Design.